Counter flow washing

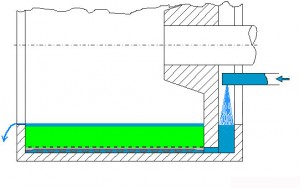

Counter current washing by flooding the rotor. At this the filtrate peeler tube will be lifted up over the edge ring level while supplying detergent at the same time

An effective counter flow washing can only be made by the use of a Krettek-concept. Therefore it is necessary that the rotor is designed as a two-chamber-system, has an unperforated wall and that both chambers are connected approx. at the level of the filter element.

If now washing liquid will be fed under rotation into the backflushing chamber it will be spread on the unperforated rotor wall according to the law of the communicating tubes and flow continuously through the sandwich filtration element and afterwards through the filter cake, formed in a preliminary stage.

The quantity of washing liquid as well as the contact time between the filter cake and the washing medium are favourably freely selectable. Especially for products with adherent pollution, which are lighter than the carrier liquid and the solids, this described process can show its best advantages.